Maintaining a parking lot is crucial for Long Island businesses – it creates a safe first impression, prevents accidents, and extends pavement life. We’ve seen that a clean, well-kept lot “signals professionalism” and invites customers. In fact, properly cared-for asphalt can last 25–30 years, whereas neglect leads to cracks, potholes and liability. Our Islandwide Paving & Masonry team often reminds property owners that simple, consistent care makes a huge difference. Below we share 12 essential maintenance steps we use on Long Island, plus pro tips on lighting, drainage, and the crews who handle this work. If you have questions or need a quote, contact us – we’d be happy to help.

Our crew uses heavy equipment to repair and resurface a worn parking lot, one of the key maintenance tasks on Long Island.

1. Regular Sweeping and Cleaning

We start with routine sweeping. Debris like leaves, litter, and dirt can trap moisture and wear down asphalt. Clearing them regularly prevents slip-and-fall hazards and pavement damage. In fact, one industry source notes that accumulated debris “poses significant hazards” and “regular sweeping removes these potential dangers, minimizing liability risks”. Clean pavement also looks better and avoids abrasive grit that accelerates wear. For example, sweeping prolongs asphalt life by keeping sand and grit from grinding into the pavement. In practice, we schedule parking lot cleaning at least monthly (more often under heavy tree cover) to keep drains clear and surfaces debris-free.

2. Removing Standing Water

Standing water is a common culprit of pavement decay. Rain or melting snow that pools on the lot will eventually seep into cracks and freeze, expanding to fracture the asphalt. We check for low spots and fix drainage issues because, as experts warn, water that sits “can seep into the asphalt, weakening the structure and making it more susceptible to damage from the freeze-thaw cycle”. Without proper drainage, even small puddles lead to cracks. On Long Island, winter freeze-thaw is harsh; one guide notes that winter “thaw and freeze cycles can cause asphalt to crack”. We keep catch basins clear and slope the pavement so rain flows away quickly. When we see standing water, we often install trench drains or regrade the area to eliminate ponding before it forms potholes.

3. Removing Oil and Gas Stains

Oil and gasoline leaks from vehicles pose a chemical threat to asphalt. Motor oil acts like a solvent: it dissolves asphalt binder and makes the pavement soft. As one expert explains, oil “alters the chemistry of the asphalt binder, making it softer and more prone to damage”. Over months this leads to raveling (aggregate loss) and potholes. We treat fresh stains promptly: cloths, detergents or industrial degreasers can lift oil before it penetrates. If oil has soaked in, we grind out the stain and apply a primer or full overlay. Left unattended, oil “softens the asphalt” and greatly increases the risk of pavement failure. In short, quick cleanup and spot repairs keep stains from becoming permanent defects.

4. Asphalt Sealing

After cleaning and repairs, we sealcoat the pavement. This is like sunscreen for asphalt: it forms a protective shield against water, UV rays and chemicals. Sealcoating can dramatically extend a lot’s life. Industry analysis notes that regular sealcoating can boost pavement longevity by “three times longer” than untreated asphalt. It also prevents weather damage; as noted, a high-quality sealcoat “defends [asphalt] against the harsh effects of UV, temperature extremes, and rain”. In practice, we apply sealcoating roughly every 2–3 years, or as soon as cracks start to appear. Each time we sealcoat, the new surface restores the lot’s appearance and keeps moisture and oxidation at bay. (Incidentally, sealcoat itself doesn’t bond well over oil spots, so we always clean and prime stained areas first.)

5. Crack Filling

Cracks are inevitable on any asphalt surface, but stopping them early is key. We use hot-pour rubberized sealants or asphalt emulsion to fill cracks as soon as they appear. This prevents water from seeping down and doing worse damage. As one paving guide explains, crack filling “stops water from seeping into the asphalt layers”, which prevents the pavement from delaminating or forming potholes. Filled cracks also protect the base layer; we avoid letting any crack exceed a quarter inch wide before sealing. Doing this consistently is a money-saver: an industry source notes that crack filling, combined with sealcoating, can postpone major projects like repaving. In short, filling cracks locks out moisture and adds years to the pavement.

6. Fixing Crumbling Asphalt (Potholes and Spalls)

Where the pavement is already crumbling or holes have formed, we perform patching. Potholes and spalls (loose edges) are trip hazards and can damage vehicles. Paving experts emphasize that unrepaired potholes “create serious liability issues”, so we fix them promptly. Our crews cut out the bad asphalt, tack-coat the edges, and compact new hot-mix in lifts. This restores a smooth surface before the damage spreads. Asphalt patching is very cost-effective for spot repairs – it “eliminates further damage” and deterioration. We also grind raveled areas and/or apply an overlay (see below) if needed. The goal is to never let small holes grow; a patched lot keeps customers safe and avoids bigger repaving bills.

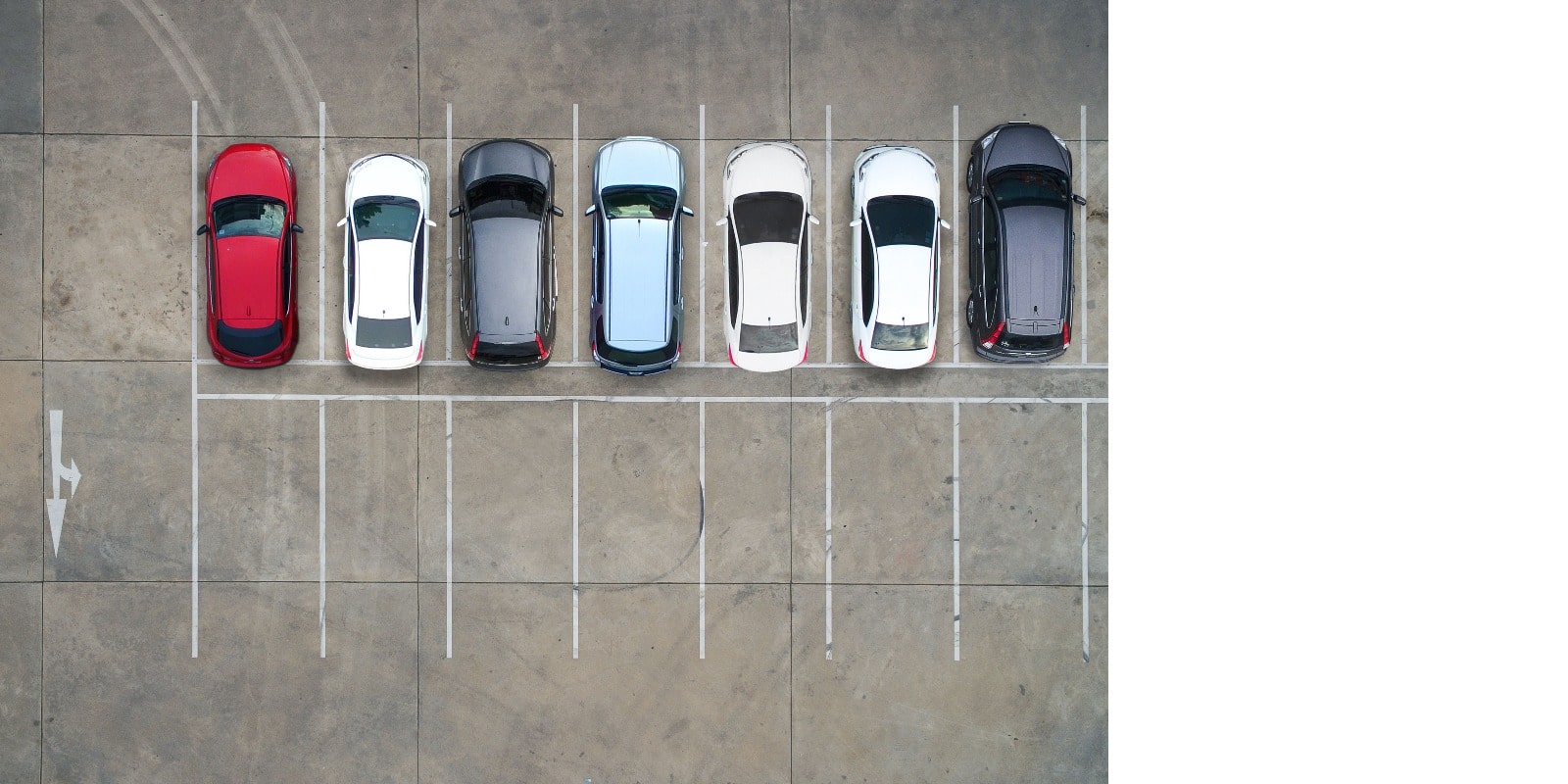

7. Striping

Clear, visible striping is part of a well-maintained parking lot. Faded lines should be repainted every few years (or sooner if worn). Proper striping guides traffic, defines pedestrian walkways, and ensures ADA compliance. For example, the ADA requires accessible parking spaces to be at least 96 inches wide with a 60-inch access aisle. We check that all striping – parking stalls, arrows, crosswalks and handicap markings – meets these specs. Fresh paint also improves safety: crisp lines show drivers and pedestrians where to go, reducing confusion and collisions. In practice, our team restripes lots on a schedule (often after sealcoating). By keeping lines bright, we help properties avoid fines and keep everyone moving smoothly.

Crisp new striping keeps a parking lot orderly and ADA-compliant. Fresh markings help motorists and pedestrians navigate safely.

8. Asphalt Overlay

Sometimes the pavement needs a “tune-up” on a larger scale. If the base is still sound (few deep cracks or potholes), we often apply an asphalt overlay. This means laying about 1–2 inches of fresh hot-mix on top of the existing surface. Overlays smooth out minor ruts and fill any remaining small cracks or pits. They are faster and cheaper than full removal; one industry source explains that an overlay is ideal “when only minor problems exist” and the subgrade is intact. In practice, we first patch or level any deep spots, then pave the new layer to restore a uniform thickness. The result is a like-new surface with no digging – an overlay often buys another 5–10 years of life at a fraction of the cost of full repaving.

9. Repaving

When the pavement is too deteriorated or old, a complete repave (mill and overlay or full-depth replacement) is the best solution. On Long Island, heavy freeze-thaw winters and decades of traffic eventually break down even well-maintained asphalt. We generally advise repaving when roughly 25–30% of the lot needs reconstruction or if the lot is 15–20 years old with constant repairs. Paving contractors note that after 25–30 years, asphalt often becomes brittle, so rebuilding is cost-effective. In practice, we inspect the lot – if large sections are cracking through, drainage is irreparable, or patches cover more than a quarter of the area, we’ll recommend a new pavement. A new pave uses a stable base layer and fresh asphalt topcoat, ensuring longevity. While it’s the most expensive option, it resets the clock: with proper maintenance afterward, the lot can last another 25+ years.

10. Seasonal Maintenance

Each season brings its own challenges, so we adjust our maintenance accordingly. On Long Island:

10.1 Spring

We clear winter debris, sweep salt and sand, and inspect for freeze damage. Early spring is when tiny cracks often appear from frost. We fill those cracks immediately to prevent water entry.

10.2 Summer

The heat can oxidize the surface, so late spring/early summer we sealcoat to prevent UV cracks. We also ensure drainage paths are clear before heavy rains.

10.3 Fall

Falling leaves can clog drains and hide cracks. We sweep leaves frequently and ready the lot for winter. We patch any summer potholes and sweep litter to prevent standpipes of debris.

10.4 Winter

We keep up plowing/salting and avoid snow banks on asphalt. If any small cracks were missed, the freeze-thaw will make them obvious by spring – that’s when we repair them.

In short, we stay on top of tasks year-round. As one pavement guide explains, the intense summer sun “can result in surface oxidation… and winter’s thaw and freeze cycles can cause asphalt to crack”. By tailoring care each season, we prevent minor damage from escalating.

11. Inspecting Lighting and Security Cameras

Maintenance isn’t just about pavement – it’s also about safety features. We routinely check all parking lot lights and security cameras. Proper lighting deters crime and prevents accidents. In fact, security experts stress that it’s “equally critical to stay on top of the parking lighting to verify they’re in working order”. We walk the lot at dusk to spot any outages, replacing bulbs and lenses as needed. We also test surveillance cameras and motion sensors. A well-lit, monitored lot is much safer: studies show poor lighting dramatically increases parking lot crimes. Good lighting and cameras protect users and protect owners from liability. When lights fail, people trip; when cameras fail, thieves act. Keeping these systems functional is a simple but vital maintenance step.

12. Ensuring Water Drainage

Finally, we make sure water never sticks around. Good drainage underpins all other efforts. Before a lot is even paved, we use surveyors to establish slopes and catch basins that force runoff away. During maintenance, we keep those flowlines clear. One expert notes that without a proper flowline, “water can accumulate in unwanted areas, leading to puddles, cracks, and potential structural damage”. In practice, we clean out storm grates and trim grass around drains so water can’t pool. If settling has occurred, we may add asphalt or regrade to re-establish the slope. The goal is that no puddle lingers after a rain – because any standing water will eventually undermine the pavement. By directing water off the lot, we protect the base layer and avoid erosion around the edges.

How Professionals Maintain Parking Lots

Over decades of paving on Long Island, we’ve learned that pros follow a strict plan. We use checklists and inspection reports, noting each crack or faded marking. We schedule sealcoating and crack-sealing at optimal times (often scheduling a spring sealcoat and fall striping, for example). We deploy the right equipment – trucks for overlay, infrared heaters for tough patches, street sweepers for debris – to work efficiently and safely. In short, professional crews never skip preventive tasks. If a crack appears, we fill it that same week. If a lot is over five years old, we assess it for sealcoating. This disciplined, data-driven approach is exactly how we protect a parking lot’s lifespan. (We also stay current with industry standards and training, reflecting Google’s emphasis on expertise.) As one guidelines suggests, a little routine upkeep “can double the lifespan of your pavement” compared to leaving it alone. That’s why we emphasize a proactive maintenance program – it really saves money in the long run.

Types of Parking Lot Maintenance Workers

Paving Crews

These crews handle large repairs and construction (overlays, repaving, major patching). They operate pavers, rollers, grinders and saws to rebuild surfaces.

Sealing Crews

Experienced sealcoaters spray on the protective emulsion and restripe the lot. They often use large squeegee machines and line-striping vehicles.

Maintenance Technicians

These workers focus on day-to-day tasks like sweeping, filling small cracks, patching potholes, and checking lights. They are on-call for emergency repairs (e.g. after a storm).

Surveyors and Engineers

Before work begins, these professionals design the lot’s slope, layout and drainage. On maintenance projects, they may check elevations or plan extensive rehab. Their work ensures water flows properly and the new pavement will meet all codes (including ADA).

Together, these crews keep your lot in top shape. At Islandwide Paving & Masonry, we coordinate all of the above teams so nothing is overlooked. Our experience in Nassau and Suffolk counties means we know the local requirements and weather challenges.

Conclusion

Keeping a parking lot in excellent condition is no secret – it’s about thorough, consistent care. Following the 12 steps above will greatly extend your pavement’s life, enhance safety, and avoid expensive repairs. The Islandwide Paving & Masonry team has seen firsthand that lots maintained this way often reach 25–30 years of service, rather than half that. We combine professional-grade techniques with local know-how: for example, we ensure ADA striping standards are met (accessible stalls 96 inches wide, with marked aisles), and we plan work around Long Island’s seasons.

Don’t wait for leaks or cracks to worsen. Request a free quote from our Long Island paving experts today. We’ll inspect your lot, recommend a tailored maintenance plan, and give you a firm price. Let us help protect your investment – contact Islandwide Paving & Masonry now for a no-obligation estimate.